The six main steps of iron ore processing - Multotec

When iron ore is extracted from a mine, it must undergo several processing stages. Six steps to process iron ore. 1. Screening We recommend that you begin by screening the

Онлайн консультация

Simplified flow chart showing typical iron ore

Download scientific diagram Simplified flow chart showing typical iron ore processing (Silva et al., 2021). from publication: Behavioural analysis of iron ore tailings through critical state ...

Онлайн консультация

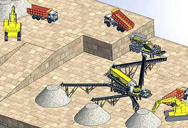

Iron Ore production in the Pilbara - Rio Tinto

2023年6月2日 Pilbara mining process diagram. Iron Ore production in the Pilbara. Activities involved in finding, mining and processing iron ore at our Pilbara operations have been

Онлайн консультация

Flow chart of the mineral processing of hematite

Download scientific diagram Flow chart of the mineral processing of hematite iron ore. from publication: An intelligent factory-wide optimal operation system for continuous production process ...

Онлайн консультация

Iron Ore Processing: From Extraction to Manufacturing

2024年4月26日 Iron ore processing is a complex and vital process that transforms raw iron ore into usable steel. From exploration and extraction to grinding, beneficiation, and

Онлайн консультация

Iron Ore Processing, General - Springer

2022年10月19日 Iron Ore Processing, General 1 Introduction Iron is the world’s most commonly used metal–steel, of which iron ore is the key ingredient, representing almost

Онлайн консультация

Iron Ore Pelletizing Process: An Overview - IntechOpen

2018年7月17日 Figure 2 shows a flowchart of a typical pelletizing plant, highlighting the additive preparation, mixing and pelletizing feed preparation, the balling step, in this case

Онлайн консультация

Iron Ore Processing, General SpringerLink

2022年10月20日 The processing methods largely depend on the characteristics of the ore itself and the nature of association of gangue with the ore. This chapter will try to give an

Онлайн консультация

Iron ore beneficiation: an overview - ScienceDirect

2023年1月1日 Flow-sheets for low-grade ore processing of different iron ore mines vary significantly; however, the underlying principle of operation is very similar. Methodology

Онлайн консультация

Iron Ore Characterization Techniques in Mineral Processing

2023年4月27日 1 Citation. 1 Altmetric. Explore all metrics. Abstract. While iron is a pivotal metal that is exploited commercially, its extraction from ores, subsequent processing and

Онлайн консультация

Iron Ore Processing - an overview ScienceDirect Topics

In India, where iron ore processing is one of the major industries, the generation of tailings is estimated to be 10-25 % of the total iron ore mined, amounting to 18 million tons per year (Das et al., 2000 ). The tailings contain silica in high percentage (40-60 %, from various locations). This makes it a suitable raw material for the ...

Онлайн консультация

Iron Ore Processing

2017年11月17日 Iron Ore Processing 500. 2 Generally, the beneficiation of high/medium grade hematite iron ores in India includes dry circuit covering crushing, screening or wet circuit consisting of crushing, scrubbing , washing and classification [3-4]. This kind of simple approach of washing and scrubbing is not sufficient enough to produce iron

Онлайн консультация

Iron ore beneficiation: an overview - ScienceDirect

2023年1月1日 Dry processing of iron ore: In dry processing of iron ore, ROM is generally crushed below 40 mm through three-stage crushing and thus segregated by screening into 10–40 and −10 mm fractions. For softer ore, tumbler index is generally low and hence lump ore is crushed below 10 mm to produce 100% fine product. Yield from the plants has

Онлайн консультация

Recent Trends in the Technologies of the Direct Reduction

2023年4月5日 Schematic flow chart of the reduction-smelting process of iron ore using non-coking or charcoal as reductants. Therefore, the availability of DRI using non-coking coal as a reducing agent is determined by the availability of iron ore with over 65% Fe quality and the availability of a cheap source of non-coking coal.

Онлайн консультация

Iron ore mining and dressing - tec-science

2018年6月21日 The flow chart shows the basic steps of how iron ore is used to produce semi-finished products of steel. The individual process steps are explained in more detail in the following articles. Figure: From iron ore to steel (flow chart) Steel is extracted from iron ores (mainly found in sedimentary rocks) and is also known as ore smelting.

Онлайн консультация

Iron Ore Processing, General - Springer

2022年10月19日 Iron Ore Processing, General 1 Introduction Iron is the world’s most commonly used metal–steel, of which iron ore is the key ingredient, representing almost 95% of all metal used per year. It is used primarily in structural engineering applications and in maritime purposes, automobiles, and general industrial applications (machinery).

Онлайн консультация

Steel Production - American Iron and Steel Institute

The blast furnace uses coke, iron ore and limestone to produce pig iron. Coal traditionally has been a key part of the coke-making process. The coal is crushed and ground into a powder and then charged into an oven where it is heated to approximately 1800°F in the absence of oxygen. As the oven is heated, the coal begins to melt so most of the ...

Онлайн консультация

Flow chart of the mineral processing of hematite iron ore.

Download scientific diagram Flow chart of the mineral processing of hematite iron ore. from publication: An intelligent factory-wide optimal operation system for continuous production process ...

Онлайн консультация

Iron processing Definition, History, Steps, Uses, Facts

iron processing, use of a smelting process to turn the ore into a form from which products can be fashioned. Included in this article also is a discussion of the mining of iron and of its preparation for smelting. Iron (Fe) is a relatively dense metal with a silvery white appearance and distinctive magnetic properties.

Онлайн консультация

Ironmaking 101 – From Ore to Iron with Smelting and Direct Iron ...

2017年10月17日 Smelting Reduction. Figure 2: The smelt reduction vessel (SRV) is the core technology component of the Hismelt process. Source: RioTinto While years of ironmaking technology innovations have optimized blast furnace productivity, two alternative processes—smelting reduction and direct iron reduction— are growing in adoption. The

Онлайн консультация

Ore Processing - Official Mekanism Wiki

2024年4月4日 Description. Mekanism adds various tiers of ore processing for better ingot yields from Silk Touch Ore. To acquire Silk Touch Ore the silk touch enchant needs to be enchanted on a pickaxe. Each tier use a

Онлайн консультация

Process flow diagram of pelletization unit

Pelletization essentially consists of formation of green balls by rolling fine iron bearing material (Hematite) with critical amount of water and Bentonite as a binder. These green balls of nearly ...

Онлайн консультация

Steel Making Process – Complete Overview with

In the open hearth process for producing steel, pig iron, steel scrap, and iron oxide in the form of iron ore or scale are melted in a Siemens-Martin open hearth furnace (Fig. 4.4), so called because the molten metal lies in a

Онлайн консультация

Improving iron ore sintering process performance - CSIRO

The challenge Processing lower quality ores . Iron ore is one of Australia's largest export commodities worth around $50-60 billion annually. According to 2017 figures, Australia produces more than 800 million tonnes of iron ore a year, mostly for use in steel production.

Онлайн консультация

Process flow diagram of Chadormalu Iron ore concentrator plant.

For iron ores with significant amounts of rare-earths [47,[320][321][322][323] [324] [325], the incorporation of rare-earth recovery steps can improve the economy of the ore beneficiation process ...

Онлайн консультация

Mineral Processing Flowsheets - 911 Metallurgist

2016年3月8日 The Mineral Processing Flowsheets shown on the following pages are based on actual data obtained from successful operating plants. Metallurgical data are shown in these flowsheets which incorporate Crushers, Grinding Mills, Flotation Machines, Unit Flotation Cells, and Selective Mineral Jigs as well as other standard milling

Онлайн консультация

Comminution and classification technologies of iron ore

2022年1月1日 Rio Tinto Iron ore processing plants in the Pilbara region of Western Australia do not involve any chemical treatment. Flow sheets for the Brockman 2 (8.7 MTpa) and Mount Tom Price (28 MTpa) processing plants are given in Figs. 8.4 and 8.5 (Kinnel, 2013). The flow sheets are relatively simple. Dry processing involves up to three crushing

Онлайн консультация

Iron Ore Pelletizing Process: An Overview - IntechOpen

2018年7月17日 The iron ore pelletizing process consists of three main steps: Pelletizing feed preparation and mixing: the raw material (iron ore concentrate, additives —anthracite, dolomite—and binders are prepared in terms of particle size and chemical specifications, dosed, and mixed together to feed the pelletizing process;

Онлайн консультация

Iron Ore production in the Pilbara - Rio Tinto

2023年6月2日 Iron Ore production in the Pilbara. Activities involved in finding, mining and processing iron ore at our Pilbara operations have been simplified in the following diagram. Rio Tinto operates 11 iron ore mines in the Pilbara and the specific sequence of activities varies from mine to mine. Excellence in planning, scheduling and quality control ...

Онлайн консультация

Ore Beneficiation - an overview ScienceDirect Topics

Life cycle assessment of iron ore mining and processing. N. Haque, T. Norgate, in Iron Ore, 2015. 20.2.5 Screening and separations. Screening is an important step for dry beneficiation of iron ore. Crushing and screening is typically the first step of iron ore beneficiation processes. In most ores, including iron ore, valuable minerals are ...

Онлайн консультация